Attempting To Fix a DC Motor

I have a 9v brushed DC motor that I used a lot. It was very fast so I decided to try to attach a small plastic fan cap to it to see how much air it can move. When I turned on the motor, it was not spinning and when I spun the fan to see if I could get it started, I then heard something rattling on the inside and it was not spinning at all. I knew that should not happen so I needed to open it up.

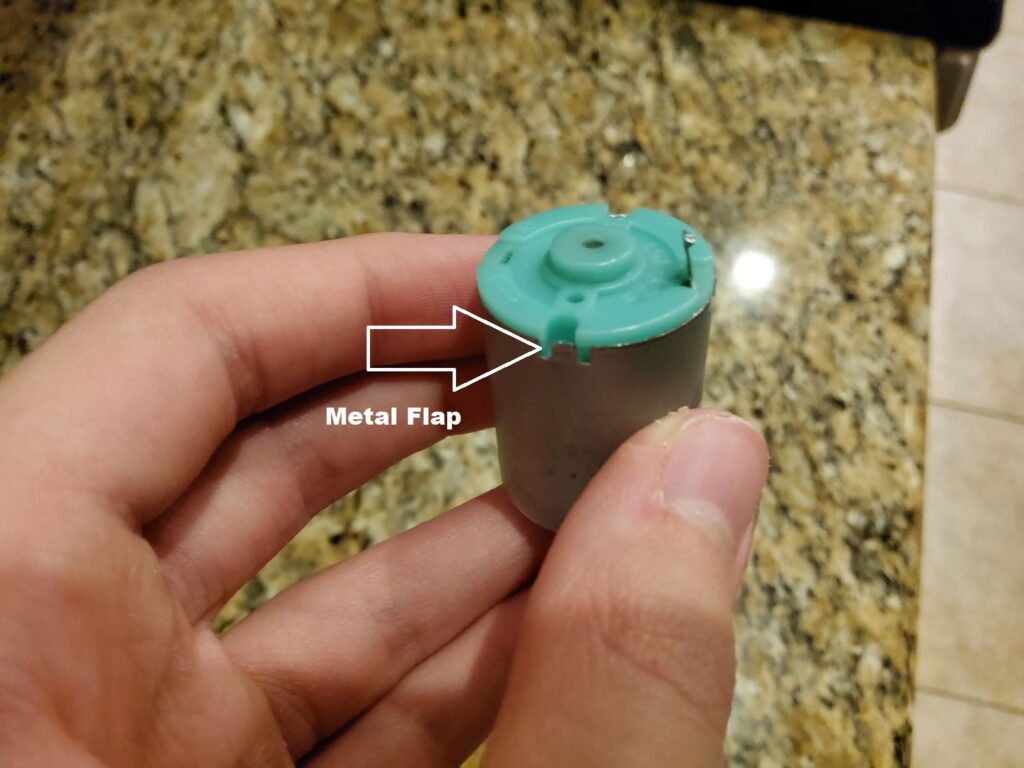

To open a motor you will see small metal flaps on the outside of the motor holding the bottom part onto the motor.

You can bend the flap up with a screwdriver. It can be hard to bend them. Once you bend all of the flaps, you can take the bottom of the motor off.

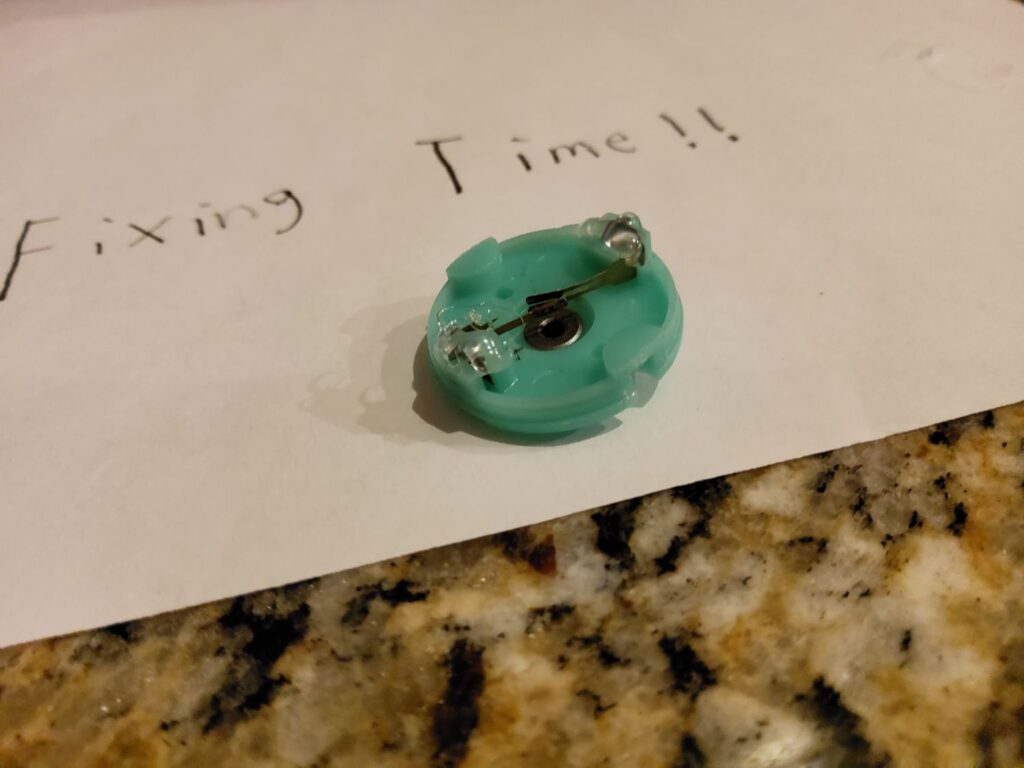

Carefully lift the bottom part off of the motor and you can access the insides of the motor.

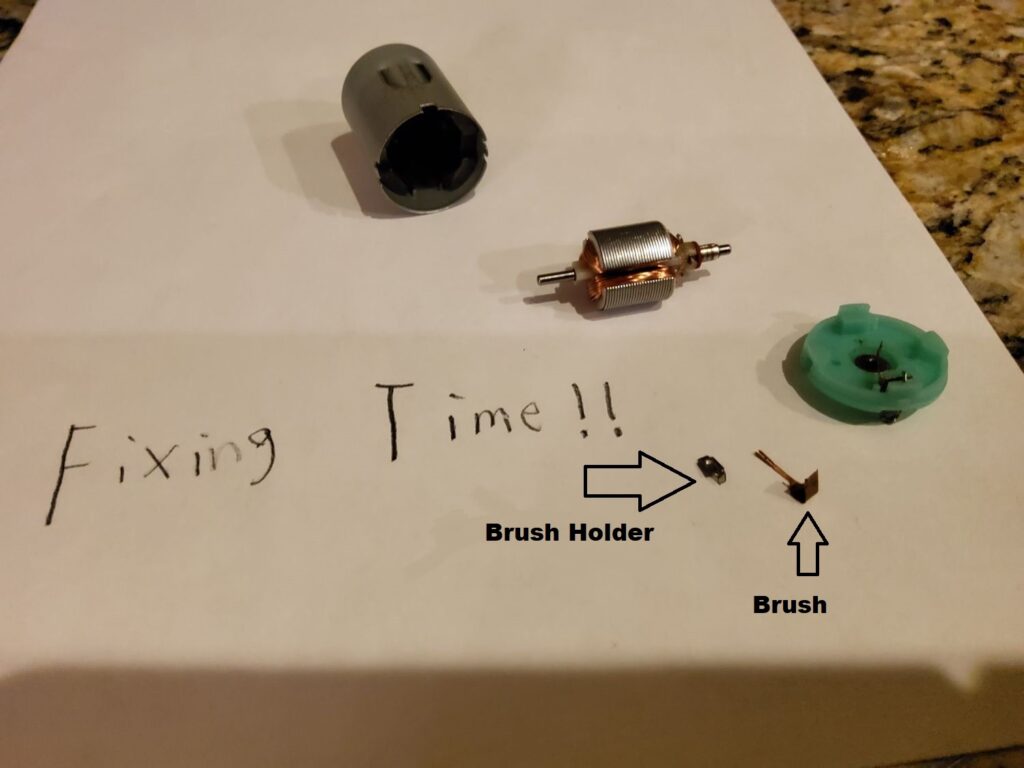

The pieces that were rattling were one of the brushes and the small metal piece that was holding the brush onto the bottom piece. After being used several times, the metal piece probably got bent and it failed to hold the brush in place.

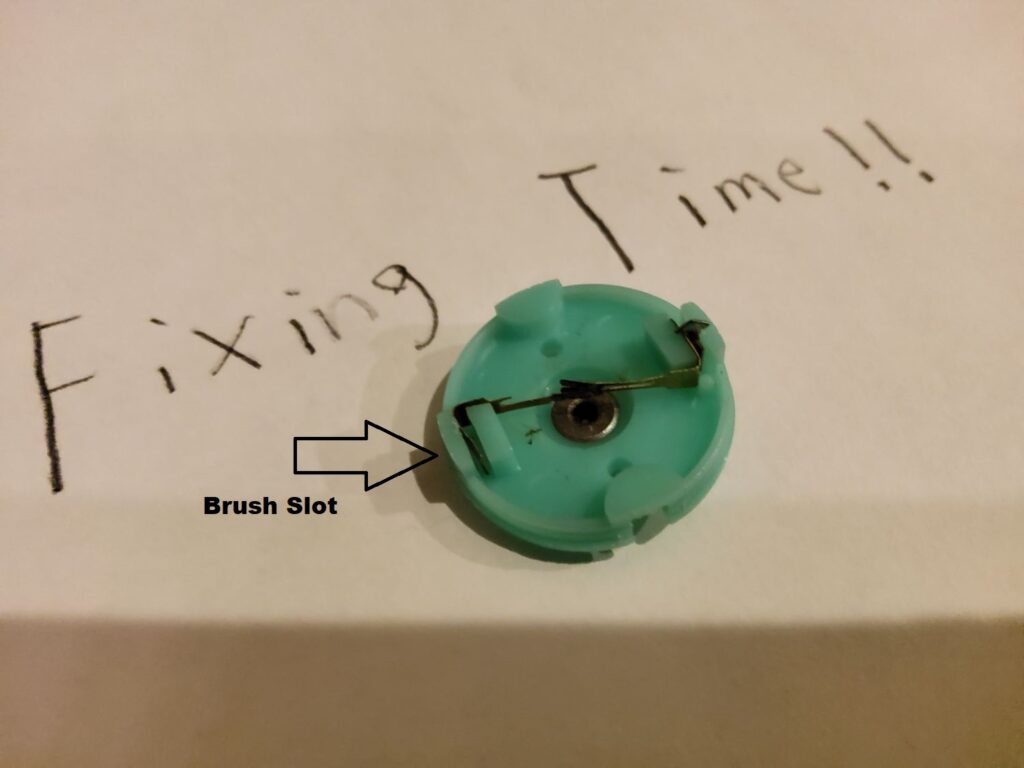

I carefully slide the small metal brush into the slot that it was inside of.

Be careful because the brushes are very thin. You may get some oil on your fingers.

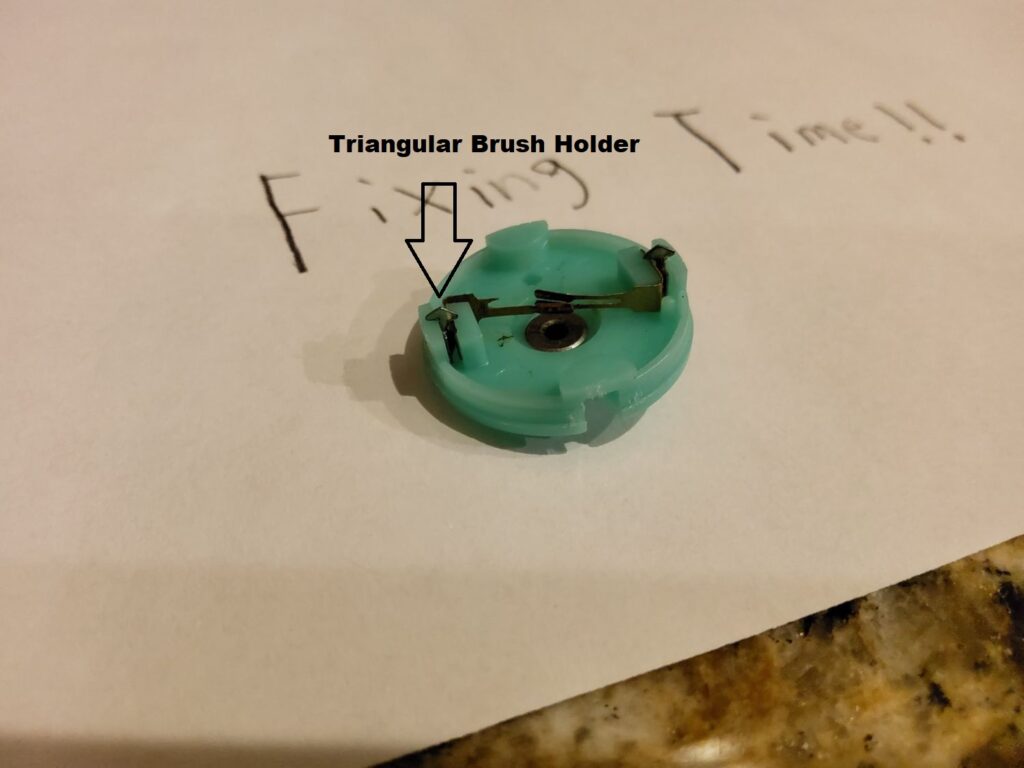

Then I carefully put the metal brush holder into the slot with the motor brush

You probably won’t need the brush holder because I will cover the top of the motor brush in glue from a hot glue gun but I will keep it for extra strength.

Put a drop of glue on the brush. I decided to put some on the other one so the same problem doesn’t happen again.

Put the rotor base with metal sections on it between the brushes. That part is called the commutator and that is what alternates the power between the three coils to make it spin.

I need to put the metal housing around the rotor and the brushes. The housing is called the stator.

I could not bend the flaps very well so I decided to put some glue around the edges of the motor to keep the bottom part connected to it. There is a missing connector on the bottom of the motor but I could just insert a jumper wire into the hole where the connector used to be. The broken connector could have also been a cause of the loose brush.

I put a fan cap on the motor and connected the motor to a battery pack. I spun the motor to get it started and it spun very fast. Now I can stay cool in the summer with this fan setup.